When it comes to selecting a custom machine shop in Vancouver, you should look at the big picture instead of just one or two aspects. The price matters, but it should be the last consideration instead of the first. In this blog, we are going to share some important tips with you to help you hire the right custom machine shop in Vancouver for your needs.

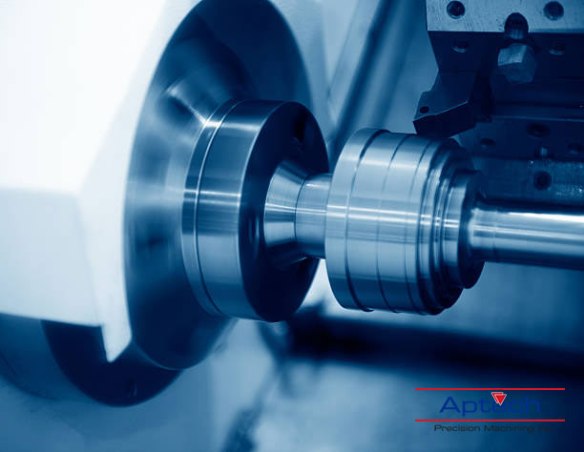

The Shop Must Be Able to Fulfill Your Requirements in the Best Way

Your first focus should be on the fact whether the shop that you have contacted is capable of fulfilling your needs. How can you determine this? Three things will help you decide this: the machines they use, the materials they use, and the skills and experience of their team. Not all materials can be the best choice for your manufacturing needs. So, you should become sure that they use the materials that can provide you with the best quality.

See the Quality of Their Recent Works

Ask the company to show you some sample works. A confident custom machine shop will never hesitate to show their latest works because they believe in their work. See the samples properly because they will give you an idea of what kind of work you can expect from them. If the shop declines to show you their latest work, then you should understand there is something wrong.

What Opinion Their Customers Have About Their Services

Testimonials and online reviews will give you an idea of what their customers think about their services. However, talking to their clients can give you the most authentic view. So, it will be better to request the shop to provide you with the name of some of their recent clients. Call them to know what they have to say about the shop.

How Long the Shop Has Been in the Market

Experience matters a lot. Many machine shops are started every year, but they are shut down in a few years because they fail to meet the expectations of their clients. Therefore, this is important for you to know how long that shop has been in the market. It will be better to consider a machine with more than a decade of experience. Besides, you should also see the certifications the shop has.

Once you become satisfied in terms of these terms, you can discuss the project cost and try to get the best price for your needs.